The Carlisle Polyurethane Systems CASE products include binders, elastomers, casting resins, surface and specialty coatings, and adhesives.

Carlisle Polyurethane Systems CASE products span a wide variety of usages. By combining years of advanced technical expertise, our scientific and R&D team delivers state-of-the-art products in the form of coatings, adhesives and binders, sealants and encapsulants, rigid casting, elastomers, foams, and more. These products perform consistently from the laboratory to each on-site application. Wherever polyurethane is involved, Carlisle has the significant technical application experience to get the job done.

Coatings

Carlisle Polyurethane Systems produces polyurethane coatings, including two-component abrasion and chemical resistant coatings, one-component athletic surfacing products, light stable aliphatic polyurethanes, and water-based specialty finishes.

Adhesives

Moisture-cured urethane binders are engineered to provide a wide range of characteristics with our polyurethane products, including chemical-resistant types and light stable aliphatic polyurethanes.

Sealants

When cured, these two-component systems are engineered to achieve optimal flow in the liquid stage with maximum adhesion. Our chemists design products with chemical resistance, hydrolytic stability, and flame retardant properties.

Elastomers

Polyurethane elastomers are two-part polyurethanes used to manufacture a variety of products. They are available in a wide range of physical and chemical characteristics, ranging in hardness from a 10 Shore A to an 85 Shore D.

- Athletic and multi-purpose surfaces

- Playground safety surfaces

- Flooring primers

- Strippable coatings

- Secondary containment

- Corrosion control

- Blast mitigation

- Indoor pad and pour

- Outdoor running tracks

- Playground safety surfaces

- Carpet pads

- Rubber underlayment

- Door mats

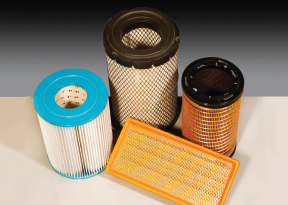

- HEPA filters

- Oil and fuel filters

- Electrical applications

- Construction

- Automotive

- Consumer products

- Bearings and bushings

- Bumper pads

- Casters and wheels

- Automotive parts

- Concrete molding

- Athletic flooring

Rigid Casting

Rigid castings are primarily used for the manufacturing of molded decorative items. Molded parts allow paint, stain, sealants, and drilling after production, as well as in-mold coating with varying finishes.

- Architectural elements

- Concrete form liners

- Stamping tools

- Flexible molding and trim

- Artificial wood

- Mannequins

Manufacturing Capabilities

Carlisle Polyurethane Systems has a variety of production processes and equipment available to manufacture varying lot sizes quickly and cost efficiently. Our diverse equipment can be utilized to manufacture a custom compound or formulation and product batches as small as one drum or as large as a tanker load. CPS has more than 40 different mixers, 25 different reactors, and milling and grinding equipment in capacities ranging from a few gallons to over 10,000 gallons.

This extensive capacity and flexibility also allow us to manufacture and deliver your order to specification and quantity on very short notice.

- Materials are available in all sizes, from pails and drums to totes and tanker loads

- Production facilities from coast-to-coast in the United States: Tennessee, Missouri, and California

- All manufacturing facilities have been issued a certificate of registration by Perry Johnson Registrars, Inc., for conformance to the ISO 9001:2015 international standard

We are positioned to deliver our products efficiently, cost effectively, and on time.